What Is SMT Technology?

When people think about massage guns, heated therapy belts, or EMS beauty devices, they usually focus on how they feel and perform — the vibration strength, the soothing heat, or the smart app functions. But few realize that behind all these features lies a crucial process called Surface Mount Technology (SMT).

So, what is SMT technology, and why does it matter so much for wellness and recovery products? Let’s break it down in a simple, human way while also showing how we at Ecozy Global integrate SMT into our massage and wellness devices.

What Is SMT Technology in Simple Terms?

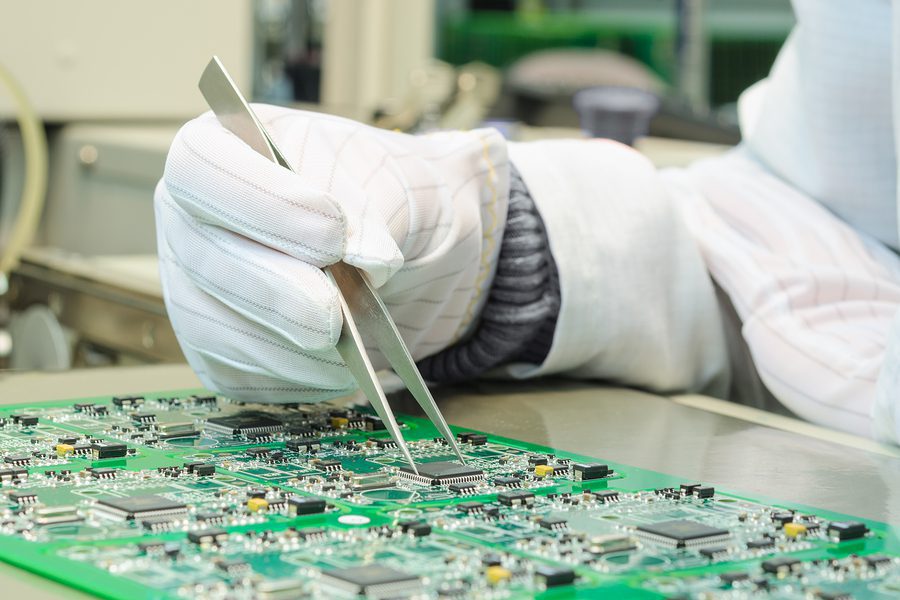

SMT, or Surface Mount Technology, is a method for assembling electronic circuits. Instead of inserting parts through holes (like in older methods), SMT allows tiny components — chips, sensors, capacitors, Bluetooth modules — to be mounted directly onto the surface of a printed circuit board (PCB).

Think of the PCB as the “brain” of your device. Without it, your massage gun wouldn’t know how to adjust speeds, your heated belt couldn’t maintain a safe temperature, and your EMS device couldn’t send out controlled electrical pulses.

By using SMT, we can pack a lot of smart technology into small, sleek designs — which is exactly what customers expect from today’s wellness devices.

![]() Why SMT Matters for Massage & Wellness Devices

Why SMT Matters for Massage & Wellness Devices

Massage and recovery tools are no longer just about motors. They include:

- Temperature sensors for hot/cold therapy

- Smart chips to control vibration speed and heating levels

- Bluetooth modules for app connectivity

- Battery management systems for long-lasting performance

All of these must be assembled with extreme precision. That’s where SMT shines — it ensures every tiny piece is positioned and soldered perfectly, guaranteeing smooth, reliable, and safe performance.

At Ecozy, we use SMT in every device we manufacture, from massage guns to heated belts, because it directly impacts product quality and user safety.

The 5 Key Steps of SMT Manufacturing

To make it easier to understand, here’s a quick look at how SMT assembly works:

-

Solder Paste Application

A sticky metallic paste is applied to the PCB to hold components and create electrical connections. -

Component Placement

High-speed machines place tiny parts — sometimes smaller than a grain of rice — onto the board with incredible accuracy. -

Reflow Soldering

The board goes through a special oven where heat melts the solder paste, bonding each component securely. -

Automated Optical Inspection (AOI)

Cameras check the board to ensure every piece is in the right spot. -

Functional Testing

We test each circuit board for real-world performance — checking vibration settings, heating functions, and power stability.

How Ecozy Uses SMT in Our Products

How Ecozy Uses SMT in Our Products

At Ecozy Global, SMT is not just a process; it’s the backbone of product reliability. Here’s how it shows up in some of our best-selling wellness devices:

-

Massage Guns with Heat & Cold Therapy

SMT integrates the motor control, temperature sensor, and LED display into a compact handle design, keeping the gun lightweight but powerful. -

L130 Heated Therapy Belt

SMT ensures precise temperature control, so users enjoy safe, consistent warmth without overheating.

Thanks to SMT, our devices stay lightweight, efficient, and reliable — three qualities that global customers demand.

5 Advantages of SMT Technology for Our Partners

When you choose a manufacturer that integrates SMT, you get benefits that directly impact your brand and customers:

- Reliability – SMT reduces errors and ensures long-lasting circuits.

- Compact Design – Smaller PCBs mean sleek, ergonomic devices.

- Energy Efficiency – Intelligent power management extends battery life.

- Scalability – SMT supports high-volume production with consistency.

- Low Defect Rate – Automated inspection guarantees fewer failures.

These advantages mean fewer returns, higher customer satisfaction, and stronger brand loyalty.

Beyond Massage Devices: Where Else Is SMT Used?

SMT is everywhere in health and wellness tech. Some examples include:

- Medical devices like blood pressure monitors and wearable ECGs

- Fitness wearables such as smartwatches and posture trackers

- Beauty tools including LED masks and RF skin-tightening devices

- Home health products like digital thermometers and oxygen monitors

It’s safe to say SMT is the invisible technology powering the smart health revolution.

Why Partner with Ecozy Global for SMT-Based Products?

At Ecozy Global (Zhejiang Hengxinrui Electronic Technology Co., Ltd.), we’ve been trusted OEM/ODM manufacturers since 2015. Here’s why top brands choose us:

- Professional SMT services with advanced equipment

- Certified quality: ISO 9001, ISO 13485, FDA, CE, ROHS, BSCI, and more

- 57+ patents proving our innovation power

- Custom PCB design and firmware programming

- 14,000㎡ production facility for scalable manufacturing

- Trusted by leading brands like Hyperice, OGAWA, and Costco

We don’t just assemble devices — we help brands bring new ideas to life with SMT at the core.

Final Thoughts

So, what is SMT technology? It’s the process that allows modern wellness devices to be smart, compact, safe, and reliable. Without SMT, your massage belt wouldn’t heat evenly, your massage gun wouldn’t run smoothly, and your EMS device couldn’t deliver precise results.

At Ecozy, we’ve made SMT a cornerstone of our production — ensuring every product we ship lives up to global standards and customer expectations.

👉 Ready to bring your next health or wellness innovation to market? Contact us today and discover how SMT-powered manufacturing can give your brand an edge.